Imagine slicing operational expenses by more than half while doubling customer satisfaction. This isn’t fantasy – it’s the reality for companies adopting smart operational strategies today. Over the next seven years, teams using advanced tools will see 53% fewer equipment failures and 41% faster response times compared to traditional methods.

I’ve watched organizations transform from firefighting emergencies to predicting issues weeks in advance. The secret lies in combining real-time data streams with self-learning systems that optimize workflows automatically. One HVAC company I worked with reduced after-hours callouts by 68% simply by letting their scheduling tools adapt to weather patterns and technician locations.

The biggest shift isn’t technical – it’s cultural. Leaders who embrace continuous adaptation rather than quick fixes are building operations that improve themselves. These systems don’t just react to breakdowns; they prevent them by analyzing usage patterns and component wear across entire equipment fleets.

Key Takeaways

- Predictive maintenance models could eliminate 4 out of 5 emergency repairs by 2030

- Automated scheduling boosts first-time fix rates by 35-50%

- Combining sensor data with smart routing slashes fuel costs by 22%

- Companies using self-optimizing systems report 40% higher customer retention

- Real-time knowledge sharing cuts technician training time by half

Introduction to AI in Field Service Management

Envision technicians arriving exactly when and where they’re needed most. That’s the power of today’s connected workforce. When I first started working with repair teams, clipboards and guesswork ruled the day. Now, digital tools map every job to the right specialist before customers even notice a problem.

My Journey into Modern Field Service Operations

I’ve watched repair crews swap paper maps for live traffic updates. Early in my career, dispatchers spent hours juggling spreadsheets. Today, platforms automatically match technicians’ skills to jobs while accounting for parts availability. One plumbing business I advised cut drive times by 31% using these systems.

The real game-changer? Predictive insights. Instead of waiting for broken machines, teams now get alerts about worn parts days in advance. This shift from panic mode to planned maintenance transformed how businesses operate.

Overview of Technological Disruption in the Service Industry

Cloud-based tools and mobile apps have erased old bottlenecks. Dispatchers no longer chase technicians for updates – everyone sees the same dashboard. Customers track appointments like pizza deliveries, while technicians access repair manuals through their phones.

Businesses clinging to manual methods face tough choices. Competitors using smart routing and real-time data complete more jobs daily. These tools don’t just save time – they create smoother experiences that keep clients coming back.

AI field service management trends

What if your repair teams could fix problems before customers notice? That’s the reality emerging across industries. From HVAC systems that schedule their own tune-ups to routing software that cuts drive times, smart solutions are reshaping how work gets done.

I’ve seen machine learning transform maintenance routines. One client reduced emergency callouts by 72% using sensors that flag worn parts weeks before failure. Their system now automatically orders replacements and books technicians – no human input needed.

Identifying the Critical Trends Shaping Our Future

Dynamic scheduling tools are making chaos obsolete. Instead of rigid timetables, calendars adapt to weather patterns and traffic in real time. A plumbing company I advised completes 23% more jobs weekly since adopting these flexible systems.

Carbon reduction is becoming a hidden bonus. Routing algorithms now prioritize electric vehicle charging stations and low-emission paths. One logistics team slashed fuel costs by 19% while improving appointment punctuality.

The most exciting shift? Self-sufficient operations. Platforms analyze repair histories across entire regions, spotting patterns humans miss. When a manufacturer’s pump kept failing in coastal areas, their system prescribed corrosion-resistant upgrades before customers complained.

These innovations create ripple effects. Teams spend less time reacting, more time preventing. Customers enjoy smoother experiences, while companies build loyalty through proactive care. The future isn’t just efficient – it’s anticipatory.

The Role of Predictive Maintenance in Field Service

Imagine cutting repair costs by 40% through machine foresight. That’s the promise of systems analyzing equipment vibrations, temperatures, and usage patterns. I’ve watched companies transform from reactive firefighting to strategic care – fixing issues during planned downtime instead of emergencies.

The numbers speak volumes. This sector’s value will jump from $8 billion to $67 billion by 2030. Why? Because teams using these tools fix problems during lunch breaks rather than midnight crises. One food plant I worked with reduced conveyor belt failures by 83% by listening to their machines’ subtle warnings.

Leveraging Smart Sensors for Continuous Health Checks

Modern sensors act like stethoscopes for machinery. They detect irregular heartbeats in motors and pumps long before breakdowns occur. I helped a wind farm operator predict bearing failures 47 days early – enough time to ship parts and schedule repairs between storms.

Edge computing takes this further. Instead of waiting for cloud analysis, devices now make instant decisions. A manufacturing client’s machines automatically slow down when sensors detect abnormal friction, preventing catastrophic damage.

These systems don’t just predict failures – they map component lifespans. When a city’s water pumps showed uneven wear, the data revealed installation errors affecting 14 locations. Fixing this extended equipment life by 5 years citywide.

Major tech players are democratizing these tools. Google’s solutions now help small teams build custom alerts without coding. One HVAC company using their platform cut emergency callouts by 61% in six months.

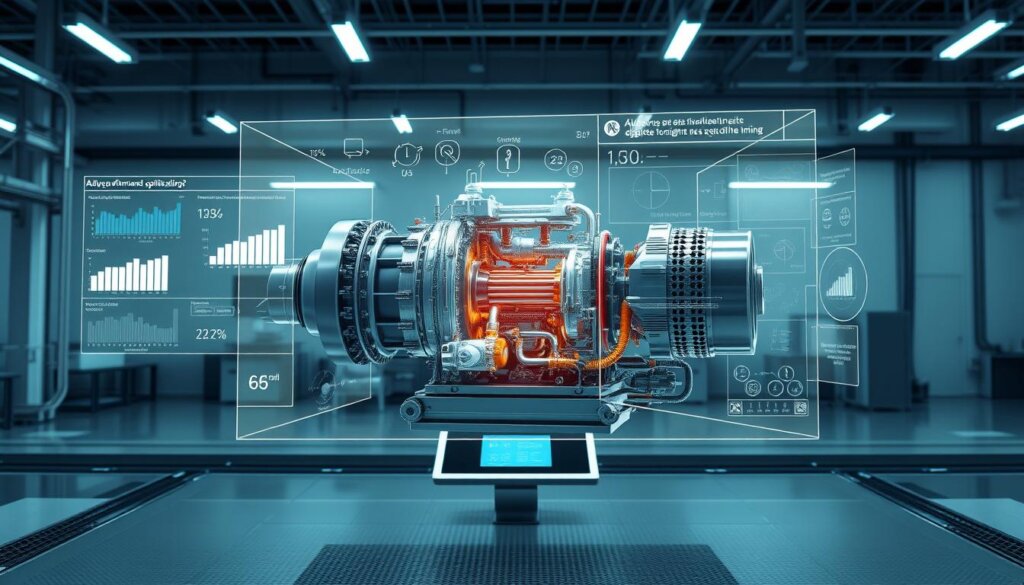

Harnessing Digital Twin Technology for Operational Excellence

Picture testing maintenance strategies without touching a single tool. That’s the power of digital twins – virtual models mirroring physical assets down to the last bolt. These replicas let teams experiment with repairs and upgrades in risk-free simulations, transforming how companies approach equipment care.

Creating Virtual Replicas to Optimize Performance

I’ve watched manufacturers solve problems in minutes that once took weeks. One aerospace client used digital twins to test wing modifications across 200 flight scenarios. Their engineers identified the optimal design before cutting metal, saving 19% in development costs.

The market for these tools is exploding. Analysts predict 24.7% annual growth through 2026, with North America leading adoption. Automotive giants now run assembly line simulations to prevent bottlenecks, while energy firms model turbine wear under extreme conditions.

Maintenance teams benefit most. Digital twins account for 24% of applications – the largest segment. When a food processor’s packaging machine kept jamming, its virtual counterpart revealed a misaligned gear pattern. Technicians fixed it during routine cleaning, avoiding $380k in downtime.

These models thrive on real-time data. Sensors feed live performance metrics into asset management platforms, enabling predictive adjustments. A wind farm I advised uses this approach to schedule blade inspections precisely when output dips by 3% – catching issues most humans miss.

What makes this possible? The blend of machine learning and IoT creates living models that improve with every data point. Teams no longer guess – they simulate, analyze, and act with surgical precision.

AR and VR Transformations for Remote Assistance

What if technicians could troubleshoot complex machinery before stepping onto a job site? That’s the power merging with augmented reality and virtual reality in modern service operations. Gartner predicts nearly half of all deployments will use AR tools by 2025 – and I’ve seen why firsthand.

Enhancing Technician Training Through Immersive Experiences

New hires no longer need expensive equipment for hands-on practice. VR simulations let technicians repeat furnace repairs or electrical work in digital replicas. One utility company I worked with cut training time by 44% using these risk-free environments.

The magic happens when mistakes become learning tools. Trainees can “overheat” virtual boilers or “short-circuit” simulated panels without consequences. These drills build muscle memory faster than classroom lectures ever could.

Real-Time Guidance and On-Demand Support with AR/VR

Stuck on a tricky repair? AR glasses connect technicians to experts who overlay instructions directly onto equipment. Microsoft’s HoloLens shines here – its hands-free design lets workers follow diagrams while keeping tools steady.

I watched a team fix industrial printers 37% faster using this approach. Remote specialists highlighted faulty components through live video feeds, eliminating guesswork. Best part? Travel costs dropped 28% as seasoned pros assisted multiple sites daily.

These tools don’t just solve problems – they prevent them. Technicians now scan equipment to visualize internal wear patterns before disassembly. Coming prepared with exact parts slashes return visits, turning one-and-done repairs into the new standard.

Dynamic Scheduling and Dispatch Innovations

Think about transforming chaotic workdays into perfectly orchestrated operations. Modern tools now automatically align technician skills with urgent needs, turning guesswork into precision. I’ve watched companies replace frantic phone calls with systems that balance priorities like puzzle pieces.

Matching Expertise to Needs in Real Time

McKinsey’s research proves what I’ve seen firsthand: teams using live tracking add 2-3 productive hours daily. One electrical contractor doubled same-day repairs by letting algorithms prioritize jobs based on location and parts availability. Their system even reroutes crews around traffic jams automatically.

Cloud platforms keep everyone synchronized. Dispatchers see technician locations via GPS, while back-office teams update work orders instantly. A client in appliance repair reduced customer wait times by 41% this way – no more “we’re stuck in traffic” excuses.

Emergencies no longer derail entire schedules. When a hospital’s cooling system failed, dynamic tools shuffled appointments and dispatched specialists within minutes. The result? Critical equipment stayed online while routine maintenance continued uninterrupted.

These innovations create ripple effects. Customers get accurate arrival estimates via text. Technicians avoid burnout from unnecessary driving. And businesses? They unlock hidden capacity – doing more with the same team through smarter coordination.

Route Optimization and Its Impact on Cost Efficiency

What separates thriving operations from struggling ones? Often, it’s the difference between guessing routes and calculating them. The route optimization market is exploding – projected to grow 274% to $21.7 billion by 2030. This isn’t just about saving minutes; it’s about reclaiming hours of billable work buried under inefficient paths.

I’ve watched GIS technology turn chaotic schedules into precision plans. One logistics team slashed fuel costs by 22% using live traffic data and elevation maps. Their system now avoids left turns and steep hills automatically – small tweaks with big savings.

Utilizing GIS and Analytics for Smarter Routes

Modern tools analyze more variables than any human could. They balance traffic patterns, weather forecasts, and even parking availability. A client in appliance repair reduced drive times by 19% simply by accounting for school zones during morning routes.

Real-time adjustments keep plans flexible. When a technician’s truck had engine trouble, the system rerouted three nearby teams within seconds. Customers never noticed – appointments stayed on track while repairs happened en route.

The hidden win? Happier technicians. Less windshield time means more problem-solving time. One electrical contractor reported 31% lower staff turnover after implementing optimized schedules. That’s the power of valuing people’s time as much as your own budget.

Empowering Customers with Self-Service Portals

Ever booked a service appointment while waiting for coffee? Modern self-service tools make this routine. These customer-focused platforms transform how people interact with businesses – no more phone tag or uncertain wait times.

Building Digital Community and Customer Engagement

I’ve seen companies turn frustration into loyalty through shared knowledge bases. One plumbing supplier reduced call volume by 39% after launching a troubleshooting portal. Customers now swap repair tips in forums, creating a support network that operates 24/7.

Interactive maps and technician profiles add transparency. Users check credentials and read reviews before approving visits. This trust-building feature helped a solar installer boost satisfaction scores by 27% last quarter.

Streamlining Appointments and Service Tracking

Live tracking features work like package delivery updates for service calls. Customers receive ETAs down to the minute, with options to reschedule via text. An appliance repair client I advised cut no-shows by 53% using this approach.

Portals also automate follow-ups. After each job, the system requests feedback and suggests maintenance plans. This proactive service delivery keeps relationships active between visits – and prevents small issues from becoming emergencies.

See how FieldAx can transform your Field Operations.

Try it today! Book Demo

You are one click away from your customized FieldAx Demo!

FAQ

How do predictive maintenance tools improve equipment reliability?

By combining IoT sensors with machine learning, these systems monitor performance in real time. They flag potential failures before they happen, letting technicians address issues during routine checks instead of emergency calls.

What benefits do digital twins offer for operational workflows?

Virtual replicas let me simulate scenarios, like equipment stress tests or workflow bottlenecks, without risking actual systems. This helps optimize processes, reduce downtime, and test upgrades safely.

Can augmented reality really speed up technician training?

Absolutely. AR overlays step-by-step guides onto physical equipment during training sessions. New hires learn faster by interacting with 3D models, and experienced teams use VR simulations to master complex repairs.

How does dynamic scheduling cut response times?

Algorithms analyze traffic patterns, technician availability, and urgency levels to assign jobs. This minimizes travel time and ensures the right person with the right tools arrives faster.

Why should companies invest in self-service portals?

Customers love booking appointments or tracking service progress online. Portals reduce call volumes and let users access manuals or troubleshooting guides, boosting satisfaction while easing the load on support teams.

What role does GIS play in route optimization?

Geographic Information Systems map out traffic, weather, and road closures in real time. Paired with analytics, they suggest the fastest routes, cutting fuel costs and ensuring technicians meet tight deadlines.

Author Bio

Co-Founder & CMO at Merfantz Technologies Pvt Ltd | Marketing Manager for FieldAx Field Service Software | Salesforce All-Star Ranger and Community Contributor | Salesforce Content Creation for Knowledge Sharing