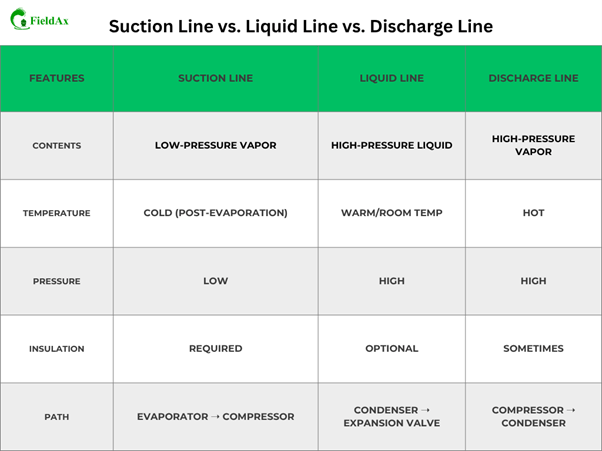

Suction line

The suction line also referred to as the gas line, vapor line, return line, or refrigeration suction line is a critical pipeline in HVAC and refrigeration systems. It is responsible for transporting low-pressure refrigerant vapor from the evaporator to the compressor.

Located on the low-pressure side of the system, this line ensures that the refrigerant reaches the compressor in a vapor state after the evaporation process. The term “suction” refers to the compressor’s action of drawing vapor from the system to maintain continuous circulation.

Role in the Refrigeration Cycle

The suction line plays a vital role in maintaining the efficiency and safety of the refrigeration cycle. After heat absorption in the evaporator, the refrigerant transforms into vapor. This vapor line then carries the refrigerant to the compressor, where it undergoes compression.

This step is crucial because allowing liquid refrigerant to enter the compressor can cause severe damage, commonly known as liquid slugging. Proper vapor flow helps maintain compressor integrity and system performance.

Technical Parameters

The low-pressure line typically operates at pressures and temperatures lower than the liquid line or discharge line. It usually ranges between 35°F to 45°F (1.6°C to 7.2°C), though exact values depend on system design and ambient conditions.

Superheat is a critical parameter measured at the refrigeration suction line. It indicates the temperature of the refrigerant vapor above its boiling point and ensures that no liquid enters the compressor. Inadequate superheat levels can lead to inefficient cooling or mechanical failures.

Design Considerations

When designing a suction line, engineers must consider:

- Pipe diameter to minimize pressure drops

- Insulation quality to prevent unwanted heat absorption

- Routing to reduce the risk of oil logging and pressure loss

Materials like copper tubing are commonly used due to durability and thermal properties. The suction line is often installed with an upward slope toward the compressor to assist in oil return and vapor flow.

Installation & Maintenance

Proper installation ensures the longevity and efficiency of the A/C suction line. Best practices include:

- Using vibration isolators

- Avoiding sharp bends

- Maintaining correct pipe support and slope

Routine maintenance involves checking for insulation damage, leaks, frost accumulation, or signs of vibration wear.

Common Issues & Troubleshooting

Common issues with the suction line include:

- Freezing due to low airflow or improper refrigerant charge

- Sweating caused by insulation failure and resulting condensation

- Blockages or restrictions that reduce refrigerant flow

- Liquid carryover, which can damage the compressor

Identifying these problems early prevents costly repairs and system downtime.

Testing and Measurement Tools

Technicians often use digital manifold gauges to measure suction pressure and superheat. Leak detection is done using:

- Electronic detectors

- UV dye

- Soap bubble methods

Accurate readings on the gas line help diagnose system imbalances or performance issues.

Industry Best Practices

Standards from organizations like ASHRAE recommend:

- Maintaining proper superheat

- Ensuring insulation on the vapor line

- Avoiding sharp bends and long, unsupported runs

These best practices ensure energy efficiency, reduce wear on the compressor, and support long-term system health.

Related Components

The suction line also known as the low-pressure line, refrigeration suction line, or vapor line is fundamental to system performance in HVAC and refrigeration units. From ensuring effective evaporation to maintaining safe superheat levels and enabling efficient heat absorption, this component plays a role far beyond simple vapor transport.

Our trusted customers