Industrial Garden Maintenance Transformation with FieldAx

From Scattered Operations to Garden Excellence

Background

The company specializes in industrial garden setup and maintenance services for corporate facilities and large-scale commercial properties. Their services include:

- Garden design and installation for industrial complexes

- Regular plant health monitoring and maintenance

- Scheduled fertilizer application programs

- Irrigation system maintenance

- Plant replacement and seasonal updates

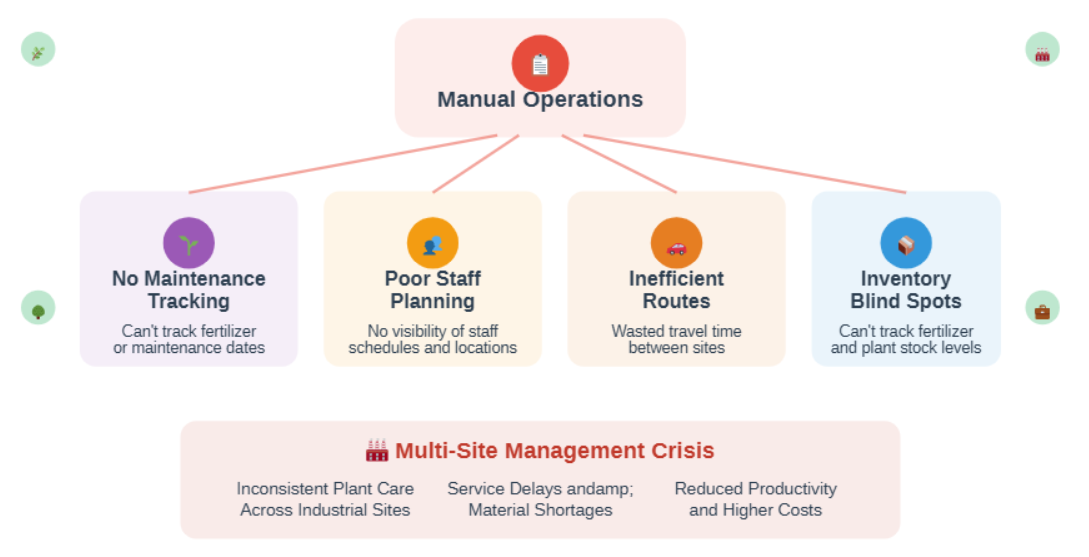

The Challenge: Fragmented Garden Operations

The company faced significant operational challenges managing multiple industrial garden sites with manual processes.

Key Problems

No Maintenance Tracking: The existing system couldn’t track when fertilizer applications were due or schedule routine plant maintenance activities, resulting in inconsistent care and potential plant health issues.

Poor Staff Planning: Managers had no visibility into field staff schedules, locations, or daily activities, making it impossible to optimize resource allocation across industrial sites.

Inefficient Route Planning: Without intelligent routing, staff traveled inefficientlybetween locations, wasting time and increasing costs while reducing daily site coverage.

Inventory Blind Spots: Managers couldn’t track fertilizer and plant stock levels in their nursery, leading to situations where teams arrived at sites without necessary materials.

Manual Coordination: Planning and scheduling relied entirely on manual processes,creating inefficiencies and communication gaps between management and field teams.

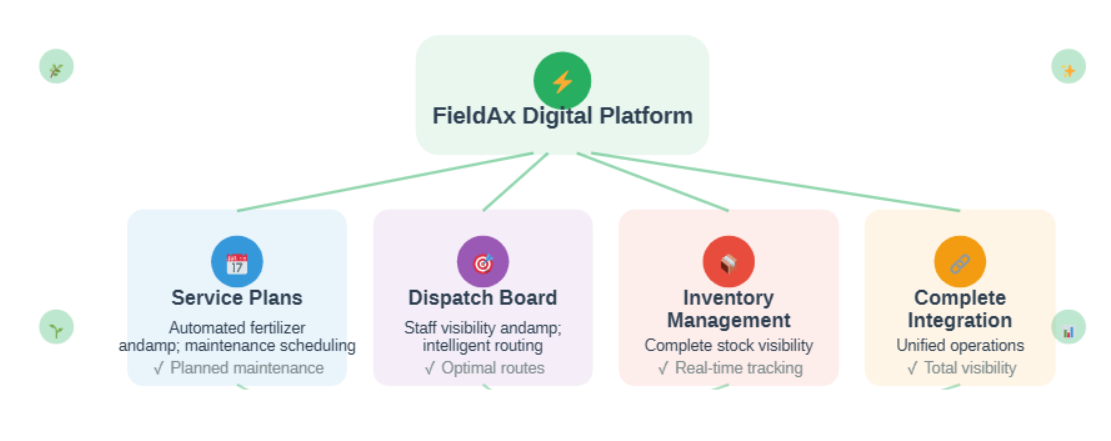

The Solution: FieldAx Comprehensive Management Platform

The company implemented FieldAx with three core components to address their operational challenges.

1. Service Plans: Automated Maintenance Scheduling

Planned Maintenance Tracking: FieldAx service plans enabled systematic tracking of fertilizer application schedules and routine maintenance activities for each industrial site.

Automated Scheduling: The system automatically schedules fertilizer applications and plant care activities based on site-specific requirements and seasonal needs.

Site-Speciflc Care Programs: Individual maintenance plans for each industrial garden ensure consistent care standards and optimal plant health.

2. Dispatch Board: Intelligent Staff Management

Complete Staff Visibility: Managers gained real-time insight into field team locations, current activities, and daily schedules across all industrial sites.

Optimal Route Planning: Intelligent routing algorithms optimize travel between industrial locations, reducing travel time and increasing daily site coverage.

Efficient Daily Planning: The dispatch board enables managers to plan and coordinate daily activities for all field staff, ensuring optimal productivity and resource allocation.

Real-Time Coordination: Streamlined communication between management and field teams eliminates delays and improves service delivery.

3. Inventory Management: Stock Control and Visibility

Complete Stock Visibility: Real-time tracking of fertilizer inventory and plant stock levels in the nursery ensures materials are always available when needed.

Automated Reordering: The system monitors stock levels and generates alerts when fertilizers or plants need to be reordered, preventing stockouts.

Site-Speciflc Inventory: Tracking of materials allocated to specific industrial sites ensures teams have necessary supplies for each maintenance visit.

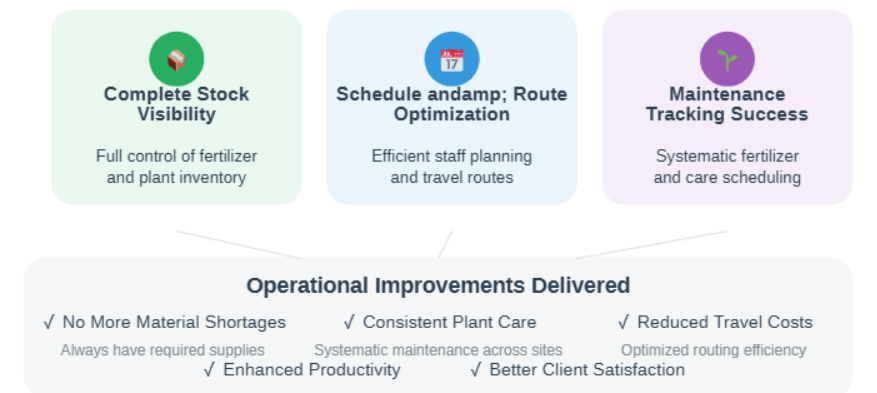

Results and Beneflts

The FieldAx implementation delivered comprehensive operational improvements across all aspects of garden maintenance management.

Complete Operational Visibility

Stock Management: Gained complete visibility of fertilizer and plant stock levels, eliminating material shortages and ensuring consistent service delivery.

Schedule Transparency: Full visibility into staff schedules and maintenance plans across all industrial sites enables proactive management and optimization.

Maintenance Tracking: Systematic tracking of planned maintenance activities ensures consistent care standards and prevents missed applications.

Enhanced Operational Efficiency

Optimized Routing: Intelligent route planning reduced travel time between industrial sites while increasing daily service capacity.

Improved Planning: Better daily planning and resource allocation enhanced productivity and service quality across all locations.

Streamlined Communication: Real-time coordination between management and field teams eliminated delays and miscommunication.

Service Quality Improvements

Consistent Care: Systematic maintenance scheduling ensures all industrial gardens receive appropriate care at optimal intervals.

Proactive Management: Complete visibility enables proactive issue resolution and preventive maintenance planning.

Client Satisfaction: Improved service reliability and consistency enhanced client relationships and satisfaction scores.

Business Impact

Resource Optimization: Better staff utilization and route optimization reduced operational costs while improving service coverage.

Scalability: The digital platform provides a foundation for business growth and expansion into new industrial markets.

Competitive Advantage: Enhanced operational efficiency and service quality differentiate the company from competitors using manual processes.

Conclusion

The transformation from scattered manual operations to comprehensive digital management demonstrates the power of integrated field service solutions in specialized industries like industrial garden maintenance. FieldAx’s service plans, dispatch board, and inventory management delivered the complete operational visibility and control needed to manage complex multi-site garden maintenance operations effectively.