Coffee Machine Manufacturer Achieves 100% Asset Visibility with FieldAx

From Machine Chaos to Complete Control

Company Background

Our client is a coffee machine manufacturer that operates across the complete coffee service ecosystem:

Manufacturing & Sales:

- Design and manufacture commercial coffee machines

- Direct sales to coffee shops, restaurants, and retail locations

- Installation and setup services at customer sites

Ongoing Services:

- Regular maintenance and repair services

- Coffee bean supply and delivery

- Customer support and technical assistance

- Equipment upgrades and replacements

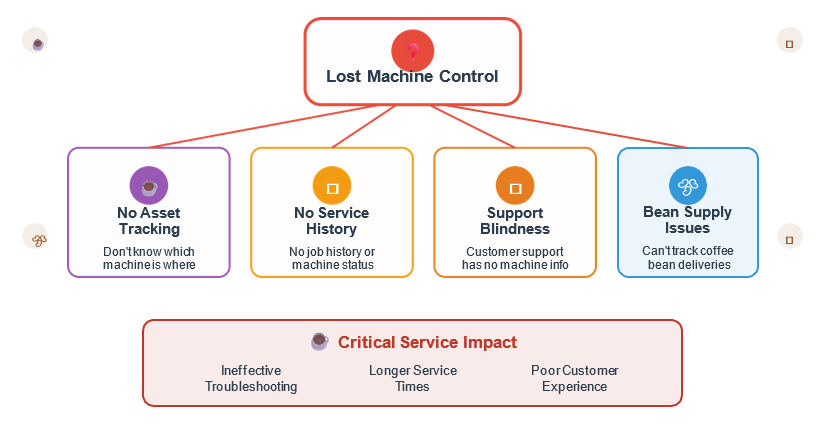

The Challenge: Lost Control of Installed Assets

As the company expanded their customer base, they lost visibility and control over their installed machine network, creating significant operational and service delivery challenges.

Asset Tracking Problems

No Machine Location Control: The company had no systematic way to track which machines were installed at which customer sites, making service planning and dispatch extremely difficult.

Missing Installation Records: Without proper installation tracking, the company couldn’t maintain accurate records of machine serial numbers, installation dates, or site-specific details.

Service History Gaps: There was no centralized system to track the complete service history for each individual machine, creating blind spots in maintenance planning and troubleshooting.

Customer Support Limitations

No Machine Status Visibility: Customer support representatives had no access to machine status information, service history, or installation details when customers called for assistance.

Ineffective Troubleshooting: Without historical context about previous issues and repairs, support staff struggled to provide effective guidance and often had to dispatch technicians unnecessarily.

Poor Service Coordination: The inability to access machine information made it difficult to coordinate between customer support, dispatch, and field technicians.

Technician Challenges

No Service History Access: Field technicians arrived at customer sites without knowledge of previous service activities, repairs performed, or recurring issues with specific machines.

Inefficient Troubleshooting: Without access to service history, technicians often had to start troubleshooting from scratch, increasing service time and reducing efficiency.

Parts and Supply Issues: Technicians couldn’t access information about previous parts replacements or coffee bean supply patterns for specific locations.

Supply Management Problems

Coffee Bean Tracking Issues: The company couldn’t track how much coffee beans were supplied to each location or when deliveries were made, creating inventory management challenges.

Supply Pattern Analysis: Without tracking capabilities, the company couldn’t analyze coffee consumption patterns to optimize delivery schedules and inventory planning.

Billing and Accountability: Lack of supply tracking created difficulties in accurate billing and accountability for coffee bean deliveries.

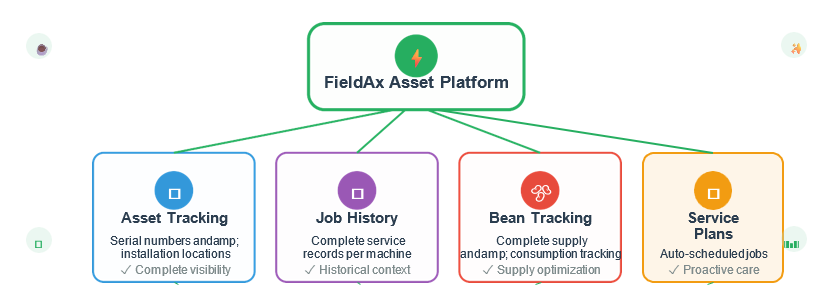

The Solution: FieldAx Comprehensive Asset Management

The company implemented FieldAx with integrated asset management, job tracking, and supply management capabilities to gain complete control over their coffee machine operations.

1. Installed Systems/Asset Tracking

Complete Machine Registration: FieldAx enabled comprehensive tracking of every coffee machine with detailed records including serial numbers, installation locations, installation dates, and key machine specifications.

Asset Database: A centralized database now maintains complete information for each installed machine, including customer details, site information, and equipment specifications.

Location Mapping: Real-time visibility into where each machine is installed enables effective service planning and dispatch optimization.

2. Job Module Integration with Assets

Machine-Speciflc Job History: The job module directly links to installed systems, enabling complete tracking of all service activities performed on each individual machine.

Comprehensive Service Records: Every service call, repair, maintenance activity, and customer interaction is recorded against the specific machine, creating detailed service histories.

Historical Context Access: Both customer support and field technicians can instantly access complete service history for any machine, improving troubleshooting and service efficiency.

3. Parts Consumption Tracking

Coffee Bean Supply Management: The parts consumption module comprehensively tracks coffee bean usage and supply for each location and machine.

Supply History: Complete records of when coffee beans were delivered, quantities supplied, and consumption patterns for each customer site.

Inventory Optimization: Supply tracking enables better inventory planning and delivery schedule optimization based on actual consumption data.

4. Automated Service Planning

Scheduled Maintenance: Service plans automatically schedule regular maintenance jobs based on machine type, usage patterns, and manufacturer recommendations.

Proactive Service: Automated scheduling ensures machines receive appropriate maintenance before issues develop, reducing emergency service calls.

Preventive Care: Regular maintenance scheduling helps extend machine lifespan and maintain optimal coffee quality for customers.

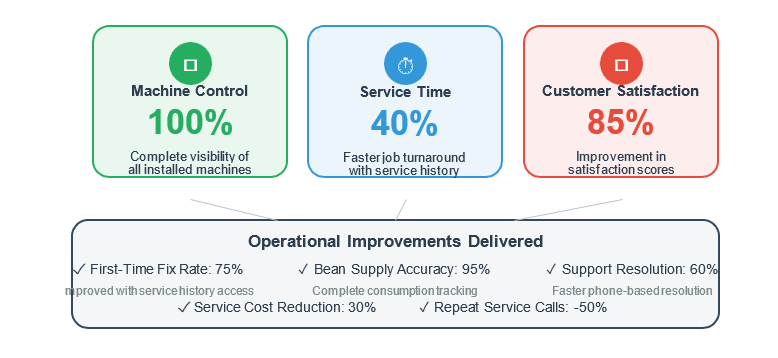

Results and Beneflts

The FieldAx implementation delivered comprehensive improvements across all aspects of coffee machine service operations.

Complete Asset Control

100% Machine Status and History Visibility: Achieved complete control and visibility over all installed machines, their locations, service history, and current status.

Centralized Asset Management: All machine information now maintained in a single, accessible database enabling effective service planning and coordination.

Real-Time Status Updates: Live visibility into machine status and service activities across the entire installed base.

Operational Efficiency Improvements

Faster Job Turnaround Times: Access to previous job history enables technicians to troubleshoot more efficiently and resolve issues quickly.

Improved First-Time Fix Rates: Historical service information helps technicians arrive prepared with the right parts and knowledge to resolve issues on the first visit.

Enhanced Service Planning: Complete asset visibility enables better service route planning and technician scheduling.

Customer Support Enhancement

Informed Customer Service: Support representatives can instantly access machine information, service history, and status when customers call for assistance.

Effective Issue Resolution: Historical context enables more effective troubleshooting and problem resolution over the phone.

Proactive Communication: Service history and maintenance schedules enable proactive customer communication about upcoming service needs.

Supply Chain Optimization

Complete Supply Tracking: Full visibility into coffee bean deliveries, consumption patterns, and inventory levels at each customer site.

Optimized Delivery Scheduling: Supply history enables more efficient delivery route planning and inventory management.

Accurate Billing: Precise tracking of coffee bean supplies ensures accurate billing and accountability.

Business Impact

Improved Customer Satisfaction: Better service delivery, faster issue resolution, and proactive maintenance significantly enhanced customer satisfaction scores.

Reduced Service Costs: Improved efficiency and first-time fix rates reduced overall service delivery costs.

Enhanced Competitive Position: Superior service capabilities differentiated the company from competitors in the commercial coffee machine market.

Conclusion

The transformation from fragmented machine tracking to comprehensive asset management demonstrates the power of integrated field service solutions in equipment-based businesses. FieldAx’s asset tracking, job management, and supply tracking capabilities provided the complete operational visibility needed to manage a distributed network of coffee machines effectively.

Key Achievements:

- 100% control over machine status and service history

- Faster job turnaround times through historical context access

- Improved customer satisfaction through enhanced service delivery

- Complete supply chain visibility and optimization

This success showcases how the right technology platform can transform equipment manufacturers from reactive service providers to proactive asset managers, delivering superior value to customers while improving operational efficiency and competitive positioning.

This case study demonstrates how comprehensive asset management solutions can transform equipment-based businesses, providing the visibility and control needed to manage distributed assets while delivering exceptional customer service.